Heat monitoring

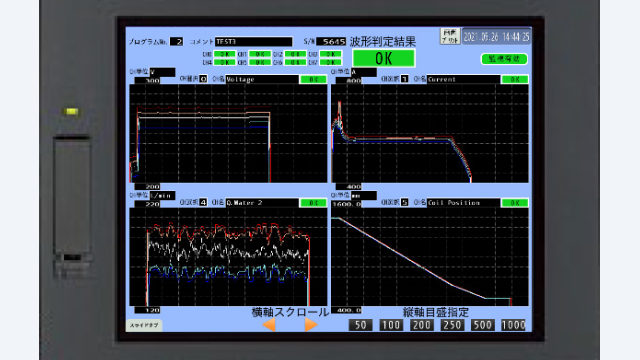

Monitors quality by performing comparisons with the waveform patterns of satisfactory products to ensure that the induction heating is being performed properly.

Flow monitoring

Monitors cooling, which is an important element of the hardening process. By capturing flow meter values, flow rates and timing are compared with the waveform patterns of satisfactory products.

Positioning monitoring

By capturing servo and displacement sensor values, waveform patterns are compared to monitor whether the positional relationship between the coils and the workpieces is correct.