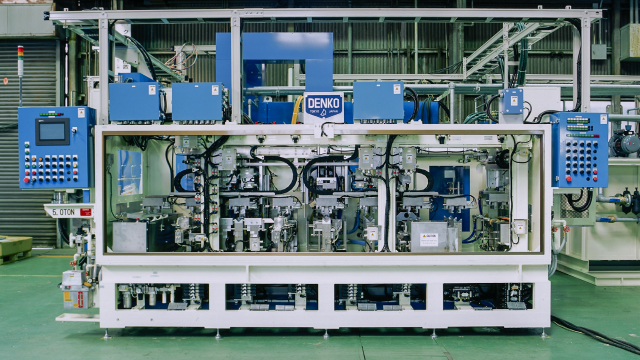

In addition to partial hardening of hollow and solid rack shafts using direct quenching, DKK can perform a wide range of heat treating operations, including full periphery traverse hardening using Dual Frequency Combined Heating.

We also have experience in the manufacture of non-oxygen hardening equipment using nitrogen gas for racks provided with ball screws in the shaft area which are used in luxury automobiles. The fastest processing time is 21 sec/unit.

We can propose a wide range of hardening methods to meet your needs.

Direct Resistance Heating Method

Hardening is performed by applying high-frequency current directly to the rack tooth and back surfaces. As hardening is performed only on the necessary portions, low-distortion machining is possible. We have a long and diverse track record of using this method.

Induction Heating Method

Arbitrary distortion adjustment can be achieved by performing scanning hardening on the entire tooth and back surfaces and providing a mechanism to correct irregularities in the workpiece by applying pressure from the front, back, left, and right during heating. For ball-screw rack shafts, atmospheric hardening in nitrogen gas is also available to prevent oxidation during the heating process. Dual-frequency combined hardening, in which the tooth surface and ball-screw portions with different heat treatment specifications are processed with scanning hardening in a single step, is available as well.

What are Racks?

Racks are a component of the mechanism which converts the rotational motion of the steering wheel into reciprocating left-right motion in order to change the direction of the vehicle’s wheels.