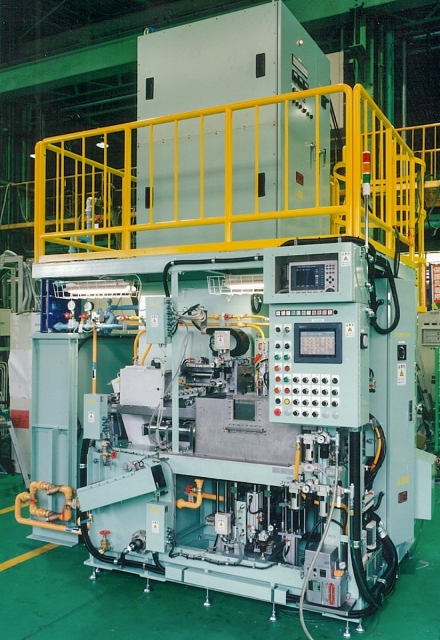

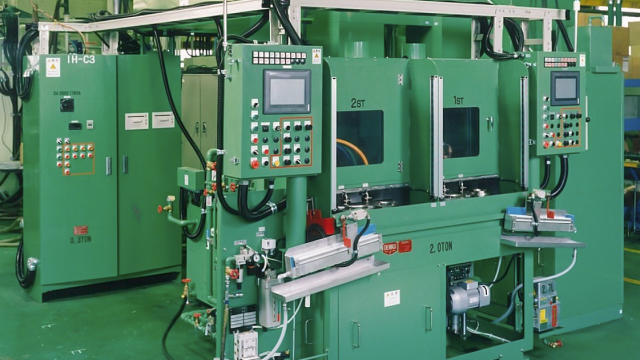

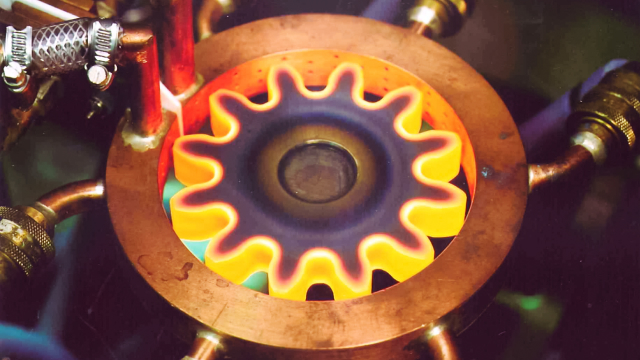

This equipment is used to harden the gears used in such equipment as automatic transmissions (AT), continuously variable transmissions (CVT), and other transmissions. With a view to protect the environment and conserve energy, more and more of our customers have been shifting in recent years from carburization and nitriding processing to high-frequency processing. Through the use of one of our advanced technologies, synthetic dual frequency combined heating systems, it is now possible to reduce heat deformation of gear parts by obtaining a hardened layer along the circumference of the gear. Various heat treatment processes are available, including full periphery traverse hardening by using Dual Frequency Combined Heating System.

This heat treating technology is used for pinion gears, worm gears, and other gears.