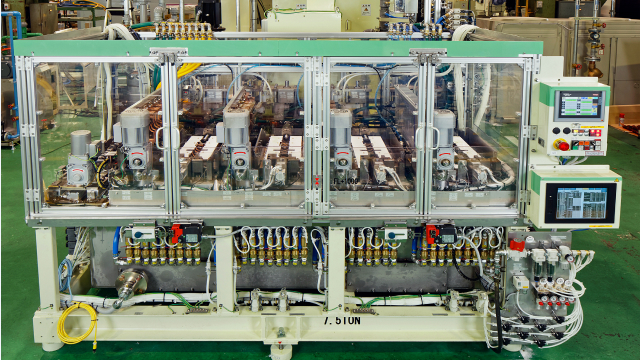

All cam parts are heated and quenched at the same time by adopting a system that allows for impedance matching among each heating coil with ease. The specially shaped coils enable uniform hardening of cast materials without unwanted cracking.

(Patent No. 3676215)

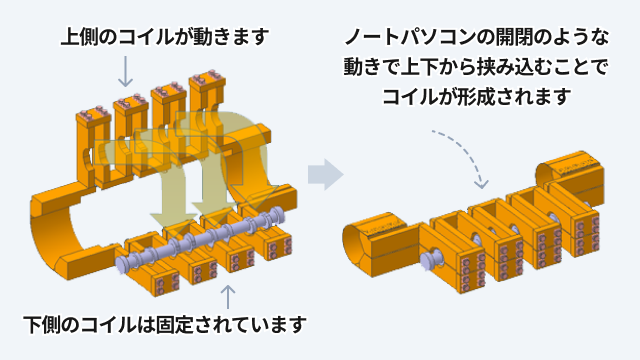

Clamshell Method

The heating coil clamps workpieces as if they are being closed up in a shell, which improves heating and cooling efficiency, eliminates heat-related cracks, and meets quality standards. The reduced machine size also saves space (approx. 50% less than our previous models).

Variable Diameter Method

The diameter of the coils automatically changes according to the size of the workpiece diameter to achieve optimal hardening. This also makes it possible to reduce the number of coils used and the frequency of coil replacement.