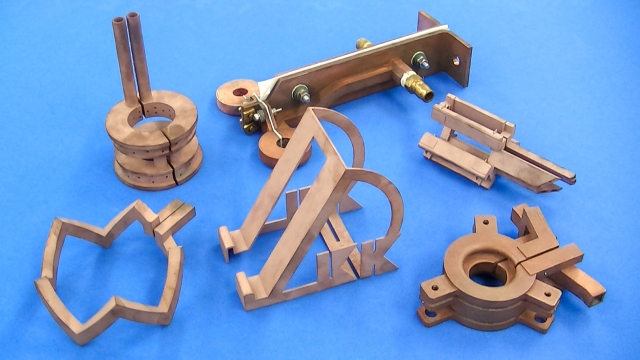

As product shapes become more complex and cycle times become increasingly shorter, demands for heat treatment quality are also becoming more stringent. In response to this, DKK is promoting the production of heating coils made with metal powder by 3D printers.

Using coils made by 3D printers offers the following advantages.

Pursuit of optimized coil designs

Coils with complex shapes that are difficult to produce by machining can be formed according to the workpieces they will be used for.

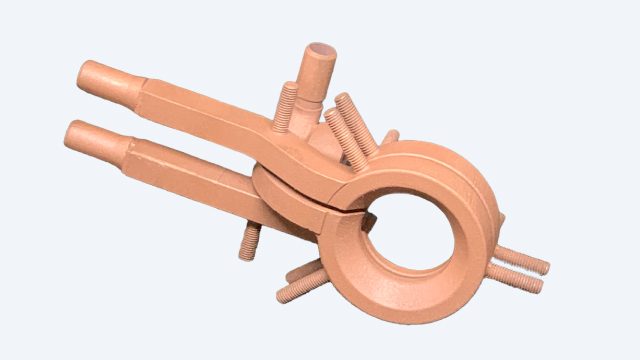

Coil production with high reproducibility

Coils with complex shapes can be produced with high reproducibility and minimal variation among pieces.

Improved durability

There are no brazing points on the coil ends, which reduces the risk of water leakage.

Shorter production turnaround time

The majority of the machining process is done by the 3D printer, which shortens production time.